Brief description

The two-chamber pressure can underwent continuous further development and refinement by us. The result of our development is an application system that combines the automatic mode of application with the requirements for an ecologically harmless propellant. Even in future.Function

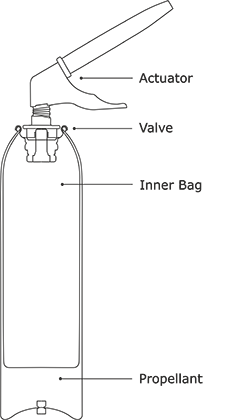

Unlike in conventional aerosol systems, our so-called two-chamber pressure can contains the product in a flexible inner bag surrounded by compressed air. When the valve is pressed, pressure is applied to this specially designed inner bag to release the product contained therein without any impurities. The components of the system correspond to the standardised components of conventional aerosols. Only an additional inner bag, which in most cases consists of ecologically harmless polyethylene, and a base plug are used; this technology allows the greatest possible technical benefits to be implemented. If required by the application, that is to say by the active substance, a propane-butane mixture can also be used as a propellant. In this case, the required quantity is far lower than that of customary aerosols. Thus, only 7-8 grams of gas are required to completely empty a can containing 200 ml whereas a conventional aerosol spray system regularly requires 10-20 times this amount of gas.Environmental aspects

None, or a reduction of atmospheric pollution caused by liquefied gas propellants! By separating the product from the outer container, there is only minor or no corrosion hazard at the can wall. This allows product formulations to be used that instead of consisting of aggressive solvents are largely water-based.Reduced waste disposal rate

Two-chamber pressure cans are filled with pure active substance to at least 60% of the gross volume of the can, in marked contrast to cans operated with liquefied gas propellants. These net capacity advantages allow smaller can dimensions compared to commonly used aerosol systems, thus producing less waste.Possible applications

Two-chamber pressure cans are ideal for dispensing highly viscous pastes, creams and gelatinous active substances in their original consistency. The absolute mechanical separation between the active substance and the propellant prevents any changes to be made to the product itself.There is, of course, nothing to prevent them from being used for liquid products as well.

Advantages

The two-chamber pressure can is characterised by perfect applicability in all positions (360°), even without the appropriate valves.The product is hermetically sealed. The active substance is almost completely sealed off from air in the inner bag.

This allows the amount of preservatives added to be considerably reduced.

No cold shock. The coolness of the spray mist in aerosol systems, which is often undesirable when applied to the body and in the veterinary and plant area (caused by the evaporation of propellant gas) does not exist here. Up to 99.8% of the contents gets used. The special design of the inner bag is very advantageous because it guarantees that the bag or the can is almost completely and profitably emptied, depending on the consistency of the active substance.

Impervious to high and low temperatures. Air is much less sensitive to temperature than liquefied gas propellants. Therefore, the effective working range of the air-operated two-chamber can from -30°C to +80°C is completely safe with respect to functional quality, reliability and safety, but the legislature does not provide for heating above +50°C.